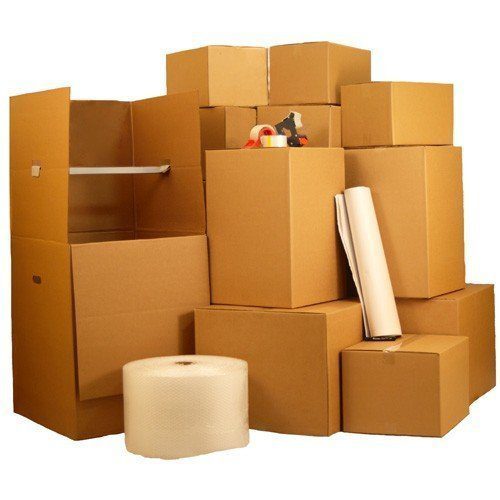

Durability: Industrial products often require packaging that can withstand rough handling during transportation and storage. Use sturdy materials such as corrugated cardboard, wooden crates, or metal containers to ensure adequate protection.

Size and Weight: Design packaging that is appropriate for the size and weight of the product. Consider factors such as dimensional weight, stacking ability, and palletization to optimize shipping and storage efficiency.

Product Identification: Clearly label the packaging with the product name, part number, and any other relevant identification information. This helps streamline inventory management and order fulfillment processes.

Handling Instructions: Include handling instructions or pictograms to indicate proper lifting techniques, orientation, and any special considerations for handling the product safely.

Protection: Use cushioning materials such as foam inserts, bubble wrap, or packing peanuts to protect the product from shocks, vibrations, and other potential hazards during transit.

Environmental Considerations: Whenever possible, use eco-friendly packaging materials and minimize excess packaging to reduce environmental impact. Consider reusable or recyclable packaging options.

Customization: Tailor the packaging to fit the specific requirements of the product. This may include custom shapes, sizes, and configurations to ensure a snug and secure fit.

Branding: Incorporate your company logo, colors, and other branding elements onto the packaging to enhance brand visibility and recognition. This can help differentiate your products from competitors and reinforce brand loyalty.

Informational Inserts: Include product manuals, safety data sheets, warranty information, or other relevant documentation inside the packaging. This provides valuable information to end-users and enhances the perceived value of the product.

Tamper-Evident Features: Implement tamper-evident seals or closures to prevent unauthorized access to the product and ensure its integrity during transit and storage.

Regulatory Compliance: Ensure that the packaging complies with relevant regulatory requirements and industry standards, particularly for hazardous materials or products subject to specific handling and labeling regulations.

Ease of Handling: Design packaging that is easy to handle, stack, and transport both manually and with mechanical equipment such as forklifts or pallet jacks.

By incorporating these elements into your packaging design for industrial products, you can effectively protect the product, streamline logistics processes, and enhance brand perception and customer satisfaction.